Technical Parameters

Contact us

Back-lit Panel Light Solution

Current location��HOME>TC-9038SBack-lit Panel Automatic Glue Dispensing and PCB Sticking Solution

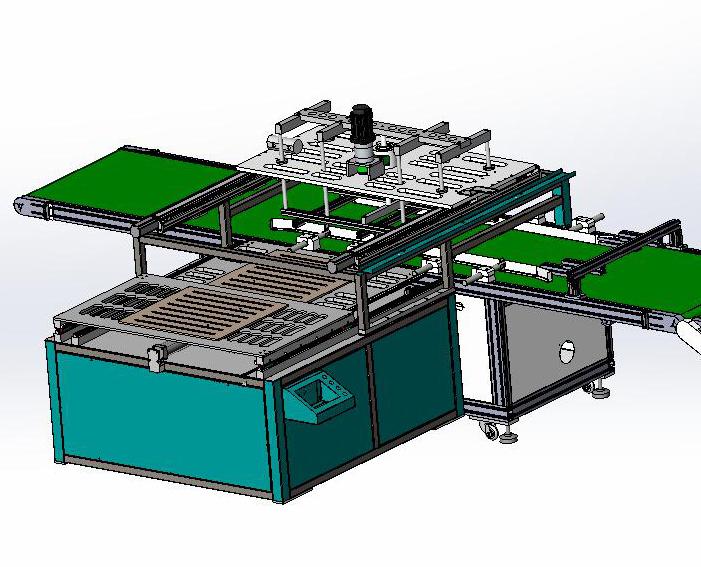

TC-9038SBack-lit Panel Automatic Glue Dispensing and PCB Sticking Solution

Principle Description:

The panel board is loaded automatically to the conveyor belt by loading device. The glue dispensing system starts to dispense glue on the board when it reached the position.The pane board will be well glued while it��s moving forwar

- Product introduction

- Technical Parameters

- Video display

Principle Description:

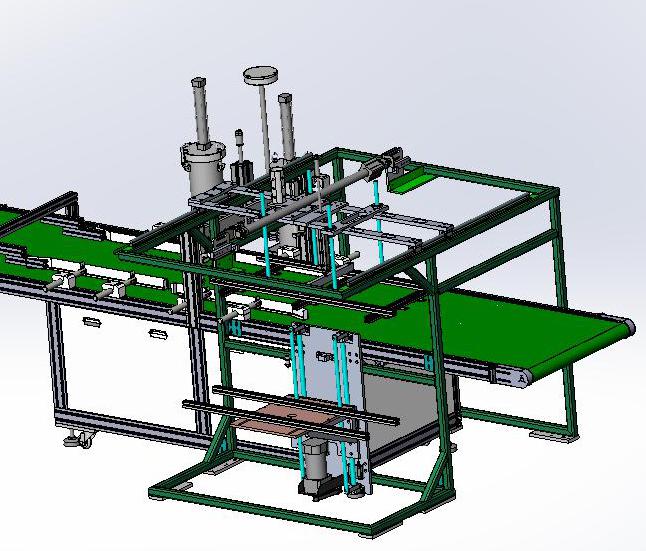

The panel board is loaded automatically to the conveyor belt by loading device. The glue dispensing system starts to dispense glue on the board when it reached the position.The pane board will be well glued while it’s moving forward. The gluing speed can be adjusted on touch screen. Meanwhile, another worker is arranged on the other side to place the PCB strips on the fixture, then PCBs can be sucked up automatically and move to the top of the glued panel board.Once the PCBs are released, PCBs can be stuck to the board perfectly. The PCB fixture is designed as two cycle station to improve efficiency.

Machine Features:

l Specially designed for back-light panel light to realize gluing and PCB sticking automation

l Glue volume and speed can be adjusted to keep stable and average glue flow

l Multiple glue valve can work at the same time to greatly improve capacity

l The width fit for panels in different size

l Designed capacity is about 300pcs/h(600*600mm panel)

l PLC control, touch screen UI available. Ease to learn and operate

Suitable glue: 2600ml package silicone

application: Back-light Panel